BOTTLE PROTOTYPE EXERCISE

Blender, 3D printer, sandpaper, spray paint

April 2025

During summer 2025 I was offered an internship at 3D Color, an industrial design model shop and graphic design comp house in Reading, OH. While I was touring the facility I had the opportunity to see the process that goes into creating a physical prototype.

After my portfolio had been reviewed, I received valuable feedback about documenting my projects. In order to best showcase not only my skills in another area, but to also demonstrate my understanding of the company's work and process, I recreated a bottle using the same process that 3D Color uses. I took this as a valuable learning opportunity to prioritize conceptual thinking as much as a finished product.

This piece demonstrates planning and conceptual design, as well as 3D modeling skills, skilled craftsmanship, and attention to detail.

SKETCHES AND IDEATION

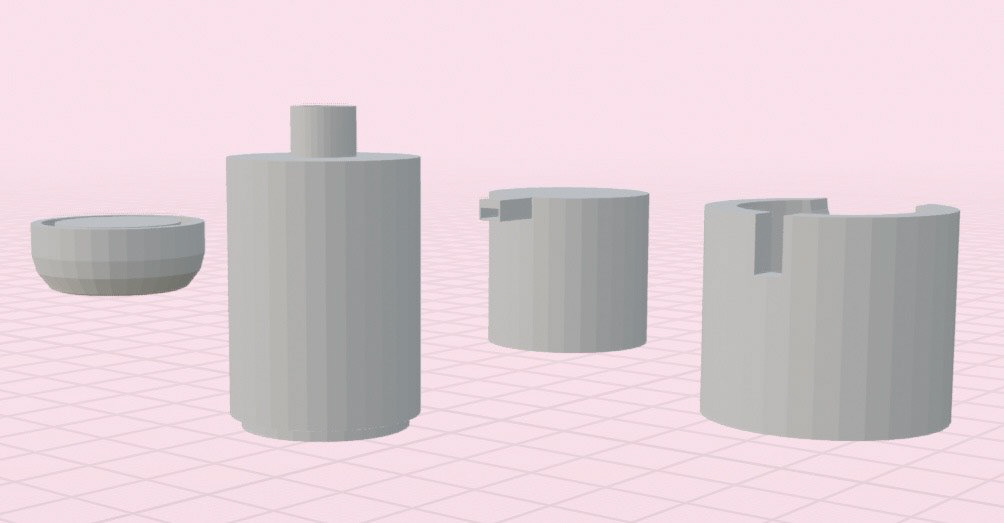

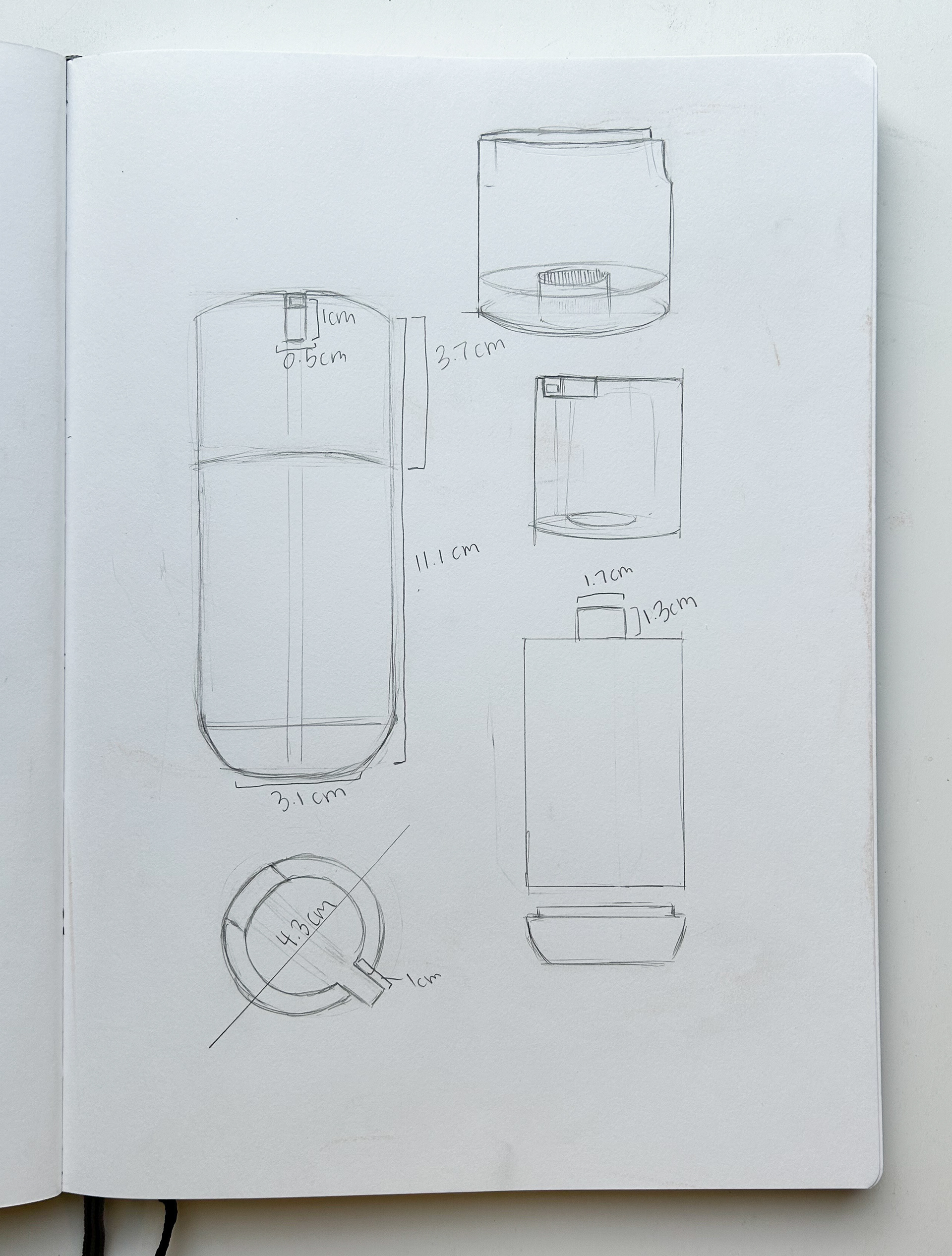

The bottle chosen for this piece is the Benzoyl Peroxide Acne Lotion by SLMD Skincare. The structure has a unique silhouette and incorporates a dynamic-submerged pump feature, these are features that would pose a challenge and were different from the average bottle.

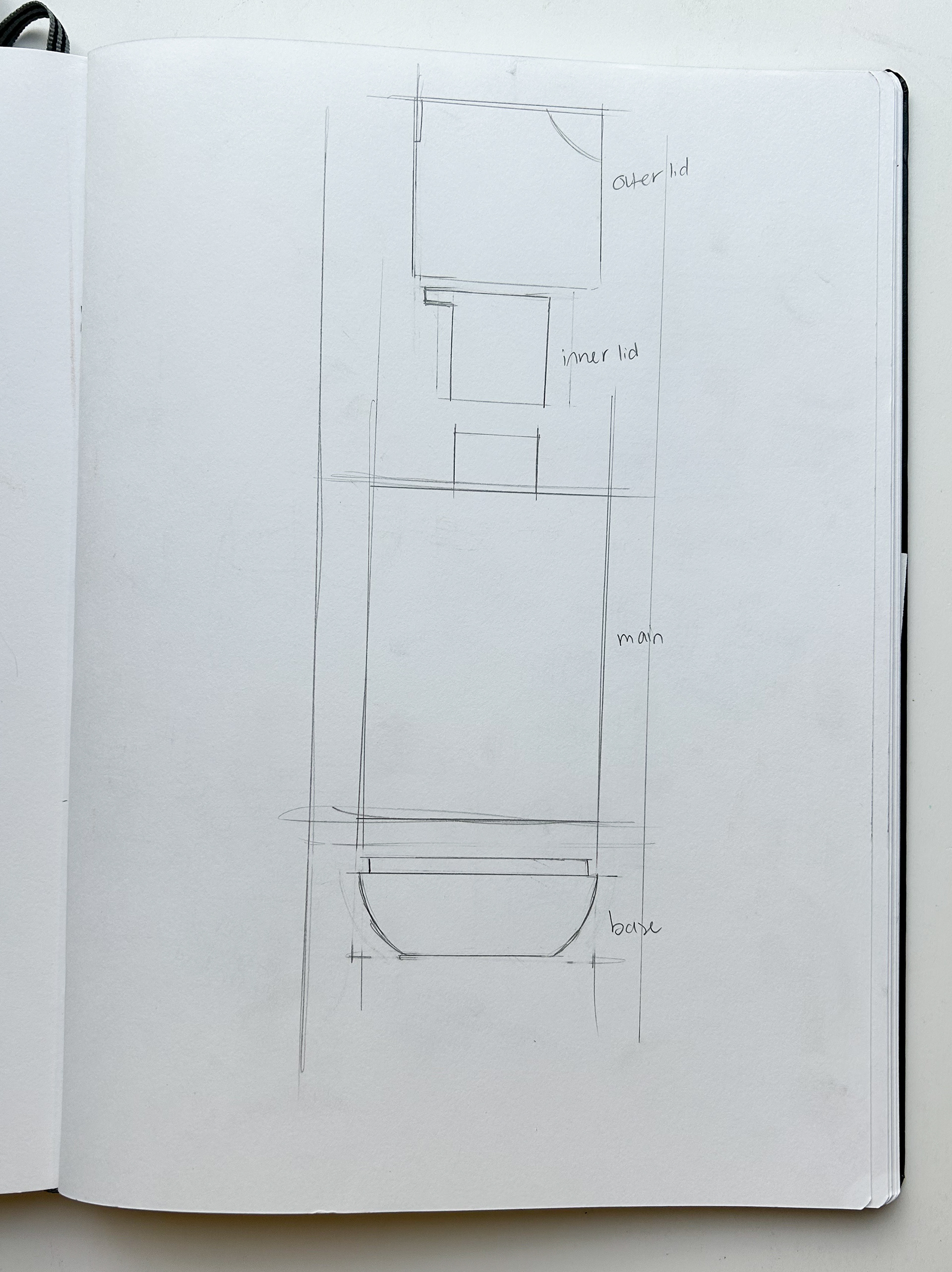

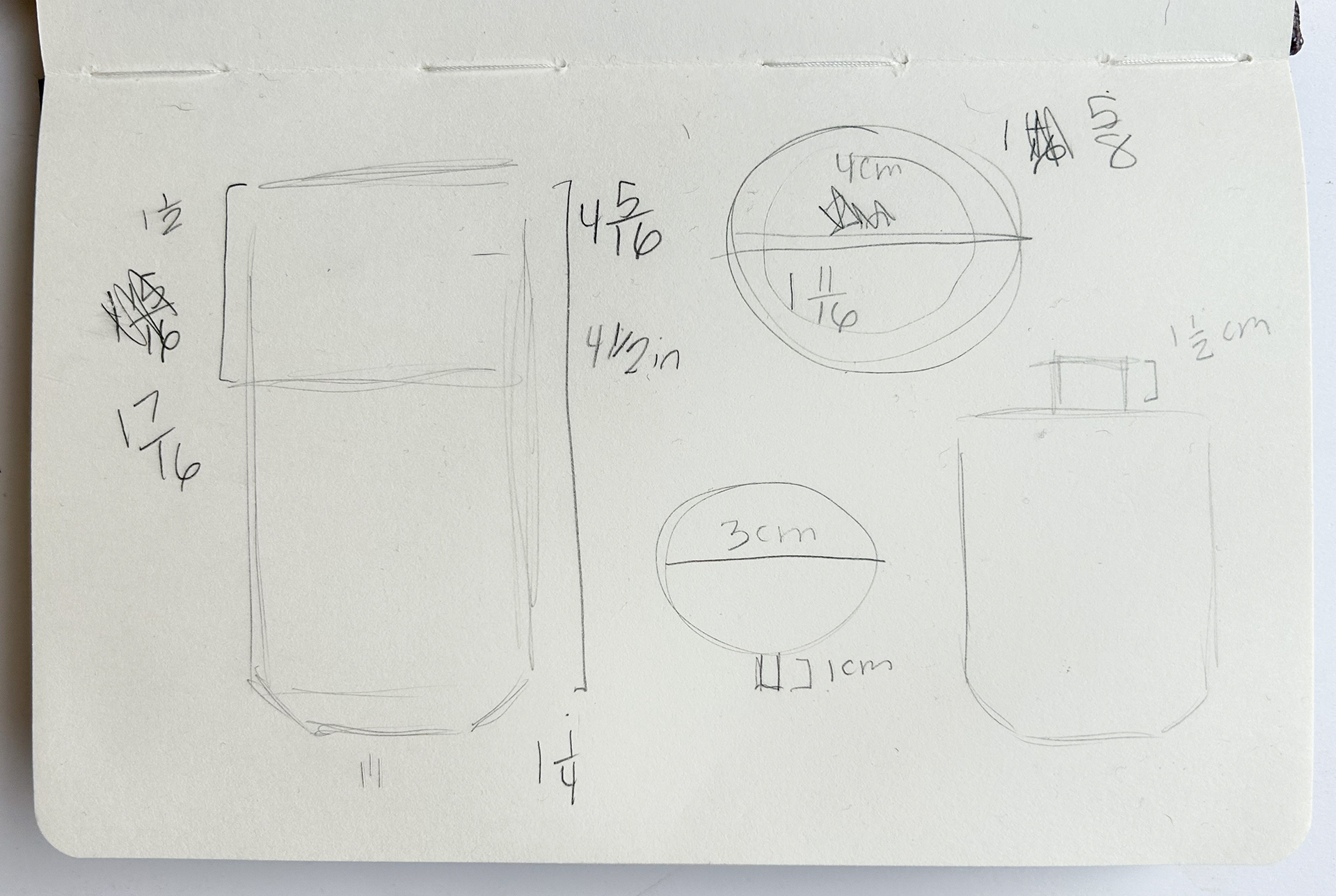

I carefully observed the different components of my chosen bottle, and mapped out where connecting pieces would be. I spent time sketching my bottle and ensuring that I conceptualized all pieces, and knew how they would work together. I took the bottle apart and closely examined where pieces would slide into each other.

Then I began to measure each piece with accuracy, while also ensuring each piece has clearance built-in for printing. Ideation started with a rough sketch intended on just getting all measurements down, then I spent time creating a finalized, clean drawing that clearly depicts the different parts and their dimensions.

PROTOTYPE #1

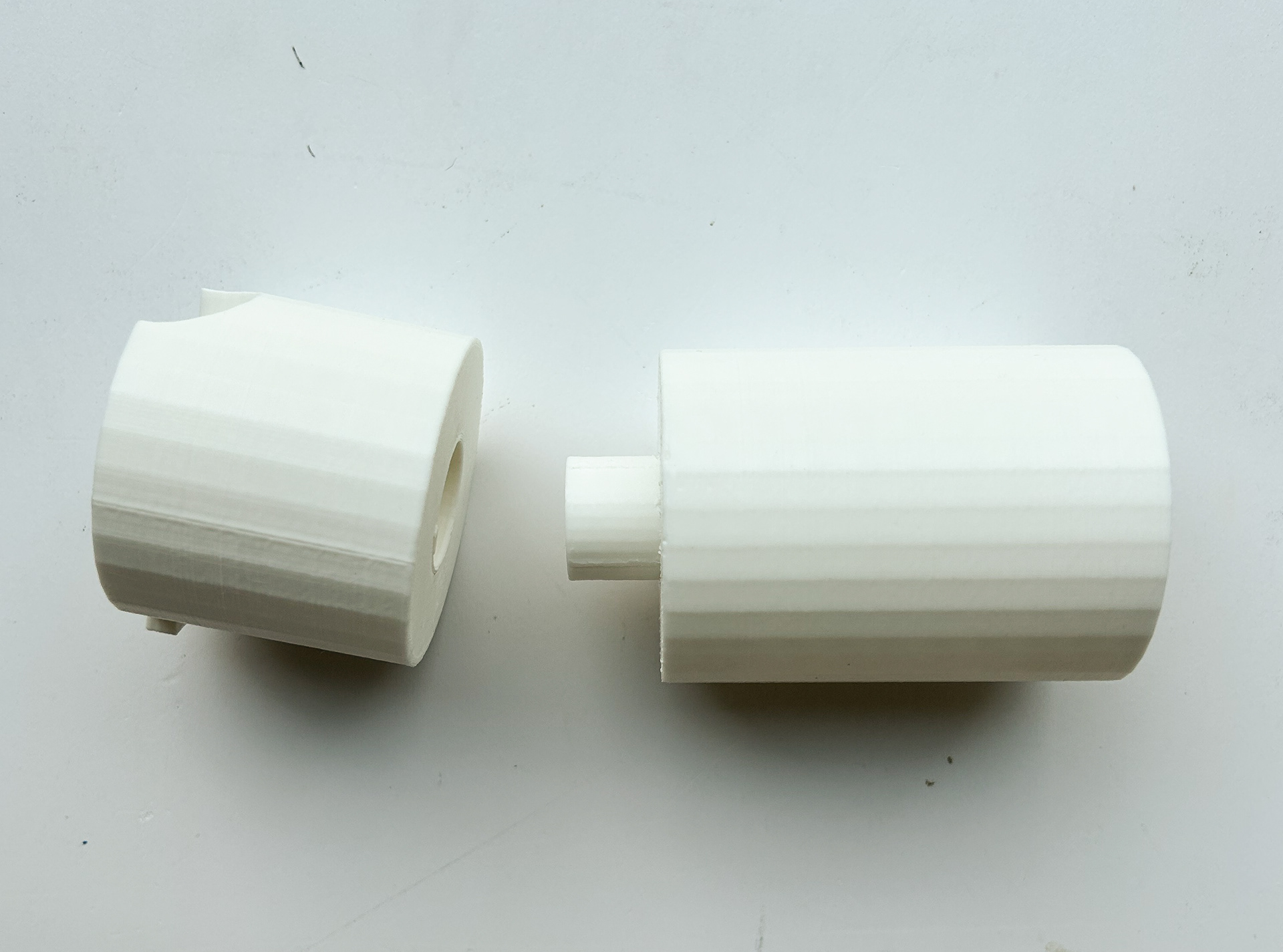

After printing the first model since the sketches and ideation stage, there were several issues that needed to be resolved.

The two cap pieces had too much clearance between the collar, leaving the cap loose and prone to falling off.

Due to the orientation of printing, the pump spout of the cap printed poorly and cracked.

The overall size of the print was too small.

PROTOTYPE #2

In the second print the clearance between the cap and collar was reduced, resulting in a friction-tight fit.

The pump cap piece was printed upside-down so that the spout would not be destroyed by supports.